LANDFILL CRISIS

Recycling Process

Clean Construction

Louis Structures owns a patented methodology that transforms household trash (MSW) into a manufactured aggregate called MSWagg™, suitable for replacing virgin coarse aggregate (gravel) in various construction applications. The methodology removes all chemicals of concern and contaminants in MSW. Processing MSW into an aggregate that meets EPA and DOT standards is achieved by solubilization, suspension, dewatering, dilution, encapsulation, and sequestration.

Lightweight aggregate (LWA) is even more in demand than standard aggregate because it reduces construction and transportation costs, which are weight determined. One cubic yard of gravel weighs approximately 2,800-3,375 pounds and costs anywhere from $12 per ton or more in addition to the cost to transport the aggregate to the job site. In applications where LWA is called for, it currently sells for about $67 per ton throughout the country (Delatte et al., 2007; Guthrie and Yaede, 2013; Ideker et al., 2013). This cost of course is significantly higher than the costs of conventional aggregates and is also a profitable opportunity for Louis Structures.

LWA could potentially be used as a fill material for embankment construction, which is expected to reduce the stresses on the subgrade foundation and control bridge slab settlement. In addition, state DOTs are evaluating the effect of internal curing (IC) using LWA and other high absorptive materials in crack reduction. An Ohio Department of Transportation study stated that LWA as an IC agent provided better workability, increased compressive and flexural strength, and improved durability in high-performance concrete (HPC). (Liu, Appelbaum, Shakoor, 2018). Additionally, when used in concrete, the inherent gas bubbles in MSWagg™ potentially contribute to “small, well-dispersed air voids in concrete that can improve workability, reduce bleeding and segregation, and improve resistance to freezing and thawing.” (Hover 1993). Based on customer specifications, MSWagg™ is from 40% to 60% lighter than gravel. MSWagg™ weighs about 1,250 pounds per yard3 and is competitively priced such that overall construction costs can be reduced by 25%.

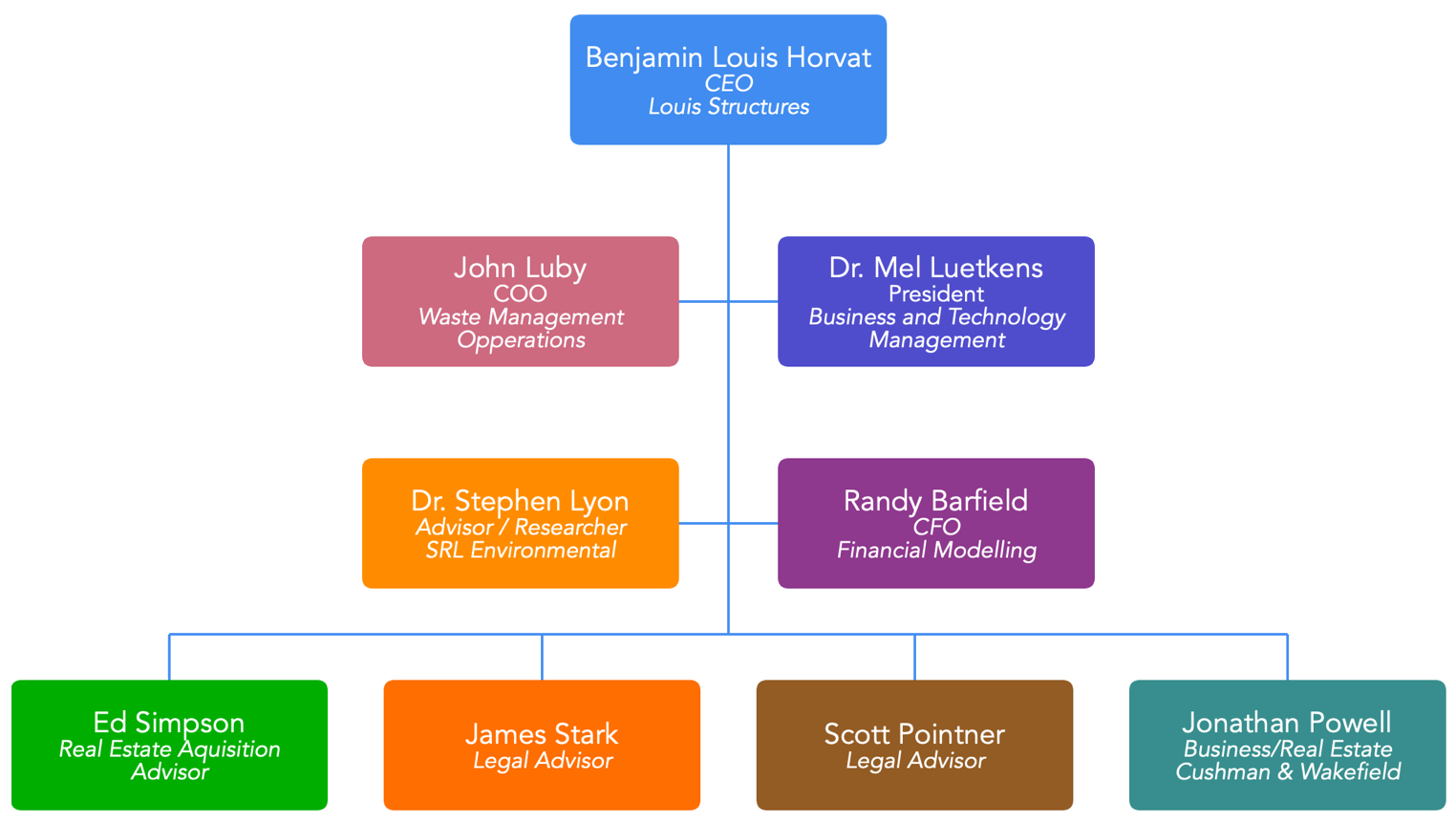

“We are thankful for a growing coalition of experts that are assisting us in the development of Louis Structures technology.”